0512-66050595

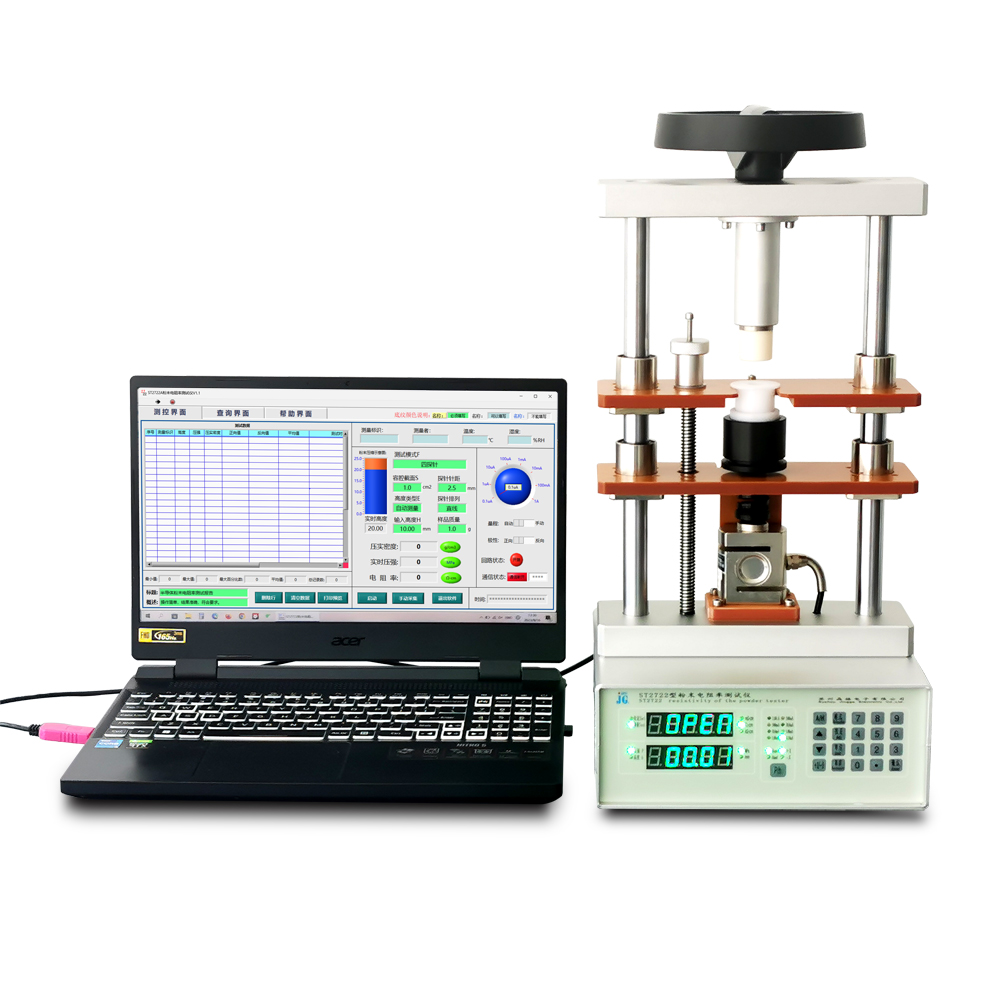

product name:ST2722 Semiconductor Powder Resistivity Tester

1、 Structural features

2、 Overview

2.1 Basic functions and standards:

The ST2722 semiconductor powder resistivity tester is an integrated and intelligent measuring instrument that combines a four terminal or four probe method resistivity tester with an automated powder tablet machine to test the "resistivity pressure" characteristic curve of powder. The four terminal method complies with relevant national and industry standards in GB/T 24521-2009 and YS/T 587.6-2006. The four probe method complies with the new GBT 30835-2014 "Carbon Composite Iron Phosphate Lithium Cathode Materials for Lithium Ion Batteries", GB/T 1552-1995 "DC Four Probe Method for Determining the Resistivity of Silicon and Germanium Single Crystals", and refers to the American A.S.T.M standard.

2.2 Complete instrument composition: The entire instrument consists of two parts: the ST2722 resistivity tester host and the SZ or SD powder tablet press, as well as supporting computer software.

The host is the core part of the electrical control display of the entire system, mainly composed of precision constant current source, high-resolution ADC, embedded microcontroller system unit, pressure and thickness display unit, and communication unit with PC.

The tablet press is composed of powder standard containers, electrodes, pressure mechanisms, pressure detection, thickness detection, connecting cables, and other units. It is a powder tablet forming device used to clamp powder (including polymer powder and metal powder), perform pressure application (tablet pressing), automatic pressure detection, and height detection. (hereinafter referred to as the tablet press).

2.3 Advantages and characteristics:

1) The design of the tester meets national standards and industry standards, is cutting-edge in China, and has obtained domestic patents. Patent number: ZL01220082173.9, with two options as follows:

The ST2722-SD four terminal method complies with relevant national and industry standards in GB/T 24521-2009 and YS/T 587.6-2006. By using the internationally recognized four terminal measurement method for current and voltage (the instrument's current source and voltmeter are connected from an independent circuit to the electrode while in contact with the sample), the error caused by the conduction resistance between the electrode and the connecting wire can be eliminated, overcoming the drawbacks of traditional two terminal measurement instruments for powder resistivity. The resistivity of powder samples can be truly and accurately measured, resulting in good repeatability.

The design of the ST2722-SZ four probe method test bench complies with the principles and specifications for powder resistivity testing in the new GBT 30835-2014 "Carbon Composite Iron Phosphate Lithium Cathode Materials for Lithium Ion Batteries", referring to GB/T 1551-2009 "Method for Determining the Resistivity of Silicon Single Crystals" and GB/T 1552-1995 "DC Four Probe Method for Determining the Resistivity of Silicon and Germanium Single Crystals", as well as the American A.S.T.M standard.

2) Synchronous continuous multi-point testing, efficient and fast, with high accuracy and good repeatability. Single loading, continuous multi-point testing of resistivity, pressure, and height synchronization can quickly draw the powder "resistivity pressure" curve. There is only a standard testing method for powder resistivity in China, which is at the forefront of the industry and recommended by the industry. It can avoid the shortcomings of the traditional asynchronous method of first pressing and demolding before four probe testing, such as large errors, poor repeatability, and even the inability to form and test scattered blocks.

3) Equipped with intelligent computer software, it can save, query, statistically analyze data, and print reports.

4) USB communication interface, with good universality and convenience. Compared to RS232 or 485 methods, these ports are generally difficult to configure on computers!

5) 8-speed ultra wide range, industry-leading. Generally, the gear range for peers is five to six.

6) It can be operated independently from a computer, with miniaturization and integrated manual/automatic operation. Easy to operate and stable in performance, all parameter settings and function conversions are entered using a digital keyboard.

7) Expandable function: The tablet press can be used independently as a regular tablet press, and the resistivity tester can also be equipped with a four probe test bench. The probe can be expanded to a regular four probe tester or a battery electrode resistivity tester.

2.6 Scope of application: This instrument has the characteristics of simple and efficient operation, high measurement accuracy, good stability, good repeatability, and convenient use for multiple purposes. It is also a new feature that distinguishes it from previous similar test benches! This instrument is suitable for carbon plants, coking plants, petrochemical plants, powder metallurgy plants, universities, scientific research departments, and is an important and excellent tool for inspecting and analyzing the quality of solid and powder samples.

3、 Technical parameters

1. Range and resolution of resistivity measurement

Resistivity: 10.0 × 10-6k ~200.0 × 103 Ω cm resolution 1.0 × 10-6~0.1 × 103 Ω cm, k=1~10

2. Classification of resistivity range and error level

|

Full scale display |

200.0 |

20.00 |

2.000 |

200.0 |

20.00 |

2.000 |

200.0 |

20.00 |

|

Range |

KΩ-cm |

Ω-cm |

mΩ-cm |

|||||

|

Basic error |

± 2% reading ± 4 words |

± 1.5% reading ± 4 words |

± 0.5% reading

|

± 0.5% reading

|

||||

3. Digital voltmeter:

Range: 10mV~100 mV, automatic

⑵ Display: 4 significant digits, larger display 999.9, decimal point and unit automatically displayed

4. CNC constant current source 8-speed wide range

Current output: The system automatically adjusts in steps, with a total of 8 adjustable DC currents of 0.1 µ A, 1.0 µ A, 10 µ A, 100 µ A, 1.0mA, 10mA, 100mA, and 1.0A.

5. Partial parameters of powder testing bench:

(1) Sample composition: There is no limit to the composition, but it must not contain components that have corrosive effects on the test bench and electrodes.

(2) Sample size: It is recommended to use sizes below 40 to 60 mesh (standard sieve), and other sizes are generally acceptable!

(3) Cup volume: Cross section: S=1.0cm2

Height: 0-20mm adjustable,

(4) Automatic height testing unit, measurement error: ± 0.02mm.

The four effective display numbers range from 00.00 to 20.00mm, with a deviation rate of ± 0.02mm.

(5) Automatic pressure testing unit,

Standard pressure: P0=4Mpa ± 0.05Mpa.

Pressure range: 20Mpa, P=0-20 Mpa adjustable.

The four digit effective display values range from 00.00 to 20.00 MPa, with a respective rate of ± 0.01 MPa.

(6) The pressure mechanism adopts manual operation and the pressure is stable and adjustable.

6. Supporting PC software

1 USB high-speed communication interface.

2. Store data in a database format, facilitating historical queries and third-party software expansion and sharing.

3. Automatically generate test reports in Excel format, including resistivity pressure curve graphs and detailed test data.

4 with test report preview, editing, and printing functions.

7. Appearance and weight of the tester

Anterior width × long × Total height=250mm × 220 mm × 540mm

Weight=10Kg

8. Power supply:

Power consumption:<10W

Input: 220V ± 10% 50Hz

9. The working conditions of this instrument are:

Temperature: 0-40 ℃

Relative humidity: ≥ 60%

There should be no strong electromagnetic interference in the studio and no shared power supply with high-frequency equipment.

Company Name: Suzhou Jingge Electronics Co., Ltd

Address: Room 202, Building 20, No. 199, Xiarong Street, East the Taihu Lake Ecological Tourism Resort (the Taihu Lake New Town), Wujiang District, Suzhou

MailCompilation:215200

Contacts :Grace

Phone:+8618762109211

Mailbox:sales@szjgdz888.com

Business customer service